Fluid handled by industries contains various particles due to atmospheric contamination, in process contamination, during handling or transportation it may be contaminated. These particles are in varied sizes and shapes and may damage or harm the equipments such as heat exchangers, burners, chilling plants, carburetors, coolers, pumps, seals, valves etc. Also, some products may need final removal of particles to enhance value; to improve further process or to achieve required clarity.

These particles are removed by installing the strainers. Y, Basket, Conical type strainer, temporary, bag type.

To cater and cover client’s wide range of requirements- flow pattern, particle sizes, slurry density and others- we specified our products in various model codes as per different construction.

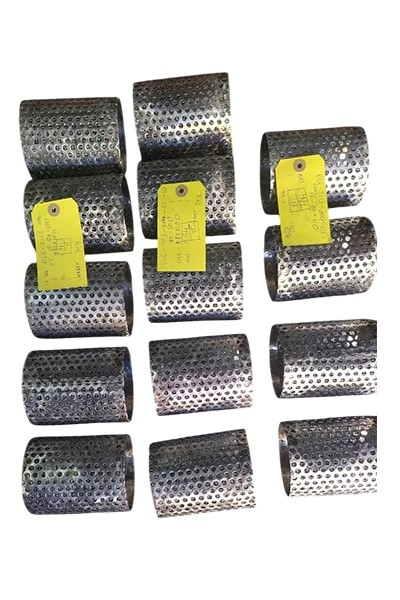

We also manufacture elements for Strainers-Basket, Y, T, Temporary-Conical, Cylindrical.

All these elements we are supplying to various strainer manufacturers, OE, end users as per their drawings, specifications or samples.

These elements also we have codified in various codes for selection and accessibility.

Some of our model codes we displayed. For more model codes and requirements, please contact factory.

| Application | Filtration |

| Features/Benefits |

|

| Size | As per requirement |

| M.O.C | AISI 304,304L, 316, 316L, MS, Monel, Haste Alloy, Nickel |